With the rapid advancement of infrastructure construction worldwide, segmental box girder precast and assembly technology has gained significant recognition from industry experts for its efficient construction speed and minimal impact on traffic flow. In practical applications, precast box girder construction methods primarily involve two methods: the long line method and the short line method. This article will provide a comprehensive explanation of segmental box girder long line precast technology and the segmental box girder short line precast method.

The first step in the long line precast process for segmental box girders is to arrange fixed pedestals that are consistent with the bridge span, taking into account factors such as the self-weight of the bridge, concrete creep and shrinkage, and construction. Then, adjust the height of the precast formwork to match the desired pre-deflection angle of the bridge. Subsequently, the entire span of the main beam is fragmented based on design specifications, segments are divided into odd or even numbers, segmental box girders are precast sequentially on the precast stations according to the sequence of odd and even numbers. The side mold moves along the sides of the station with the segmental box girder, the rear end face of the previous segment serves as the front end template for the next segment, and segments are assembled one by one on the station in order.

The advantages of long line matching precast:

(1) Platform construction is simple and requires minimal equipment, making it easier to control the alignment during precasting.

(2) The adjustment of the platform's bottom mold profile can be completed at once during precast, which simplifies the measurement process and reduces cross-operation interference between production personnel and surveyors.

(3) Since the entire bridge is precast in one stroke, the cumulative deviation factors are reduced, and it is also possible to mitigate defects caused by deviated segments through subsequent adjustments.

The disadvantages of long line matching precast:

(1) As the profile of the bottom template directly affects the final bridge alignment, imposing stringent construction requirements for platform stability and high requirements for foundation construction.

(2) Given the high cost and inability to be reused unless identical bridge girders are involved, the cost of using long line matching precast is substantial and results in significant waste.

(3) Modifying the formwork during segment prefabrication is challenging and slows down the rate of prefabrication.

(4) The substantial land requirement for platform construction is directly contributing to cost escalation.

(5) Utilizing steam curing methods on long line platforms is more challenging.

The short line method is commonly used in precast assembly projects, particularly for bridges with both longitudinal and transverse curves.

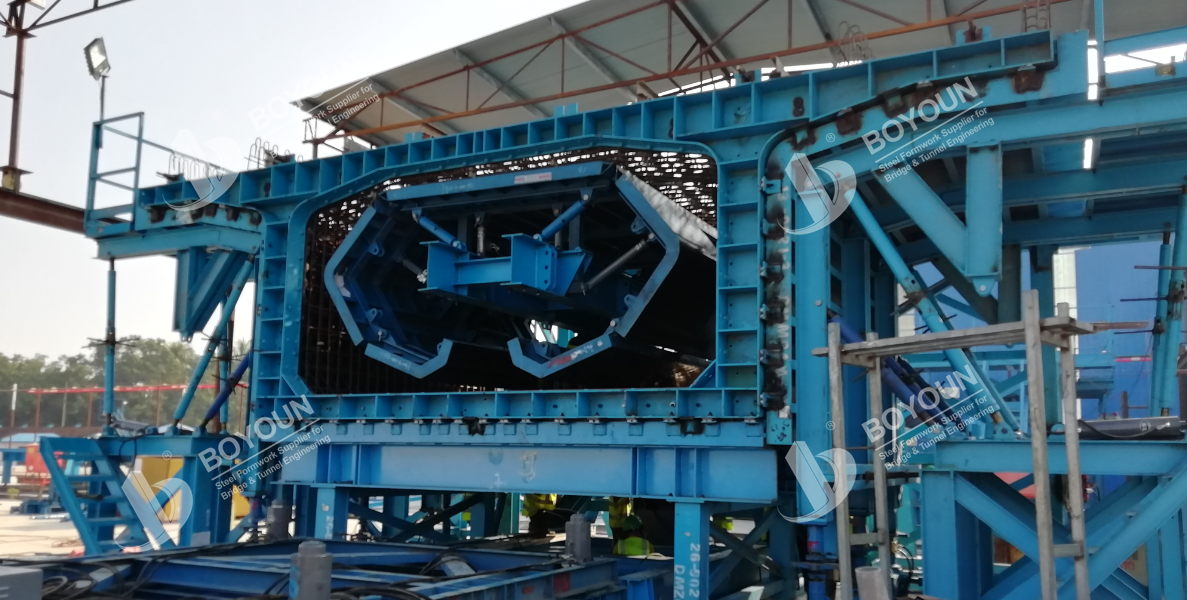

The short line method, where the platform length is equal to the length of a single segmental box girder and each segment is cast on a single formwork. One end uses a fixed steel template as an end mold, while the other end uses a previously precast segment as an end mold, precasting progressively.

During the fabrication process, the casting template and equipment generally require no movement. The bottom mold and side mold can also be adjusted to make flat curve and vertical curve segments easier to prefabricate. At the lower support, there are four hydraulic jacks and carrier tracks used to adjust the vertical and horizontal positions of the matching segment.

The geometry of the segments is based on the adjacent segments already completed and controlled according to relevant measurement results and calculated values of the pre-deflection of the girder body. After adjusting, the segment can be poured immediately.

The advantages of short line matching precast:

(1) The short line precast method only requires three segment length pedestals, making it suitable for factory production and equipment can be repeatedly used, signifying a high utilization rate of the short line method bottom molds.

(2) The short line method produces segments that facilitate steaming curing and reduce the steaming curing time.

(3) It has a smaller footprint, conserving ground resources.

(4) Given that its templates and other equipment can adjust flat and vertical curves, a variety of beam types can be precast, suitable for construction projects with multiple segment types.

The disadvantages of short line matching precast:

(1) Given that each assembled beam is relatively small, this leads to frequent turnover and extends the construction period.

(2) The rigidity and flexibility of precast formwork in short line methods have high demands, which increase construction requirements.

(3) The construction precision requirement is significantly higher than in a long line method, making construction more challenging.

Both the Box girder long line precast method and the box girder short line precast method have their pros and cons. In practical application, it's crucial to select the appropriate precast method based on the project's specific circumstances and implement effective technical measures to ensure the structural quality and safety of the bridge.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn