On May 30, 2025, as the first light of dawn broke over the Port of Houston, the first batch of double T-beam formwork delivered by Boyoun to the U.S. market completed customs clearance and unloading at the port of destination. On the same day, Boyoun once again received thanks and positive feedback from the U.S. customer: "Thank the Boyoun team for their efforts, and the formwork quality is excellent."

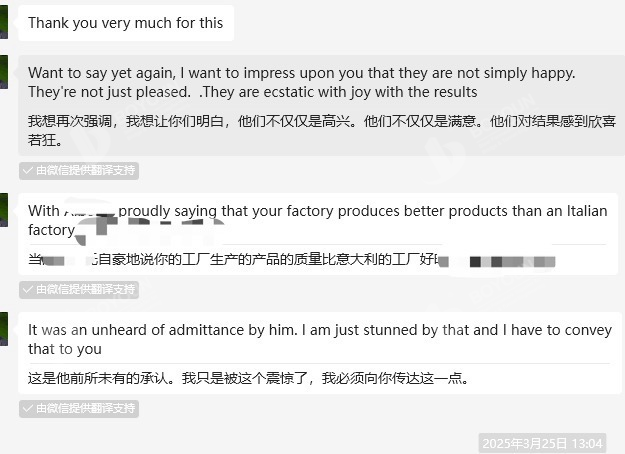

As early as March 2025, the product passed the final acceptance. Before preparing for factory shipment, the U.S. customer was thrilled with the final inspection report and results issued by SGS, an internationally renowned third-party inspection agency. Their technical director gave Boyoun's formwork the highest evaluation of his career: "Boyoun's formwork is superior to similar products from European countries!"

The successful delivery of this batch of formwork marks Boyoun's phased victory in establishing a foothold in the markets of developed countries in Europe and America!

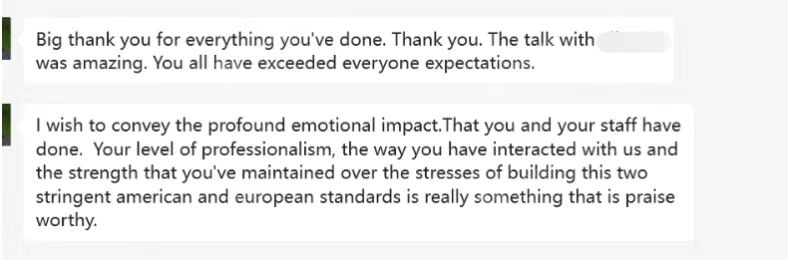

Behind the high recognition from clients with high standards and strict requirements lies Boyoun's years of business philosophy of "pragmatism, integrity, and contract fulfillment". As an industry and trade integrated enterprise, awarded the "Individual Champion Product" by the Ministry of Industry and Information Technology, it has deepened its expertise in formwork design, R&D, and craftsmanship for 20 years, accumulated 10 years of international project production and delivery experience, and established management norms of "customer-centric focus, quality standard, and process planning improvement, and full-process quality control responsibility system" based on the delivery of over 1,200 domestic and international projects. These efforts consistently meet the quality standards of increasingly high-standard orders at home and abroad.

This project represents Boyoun's highest quality standard order to date.

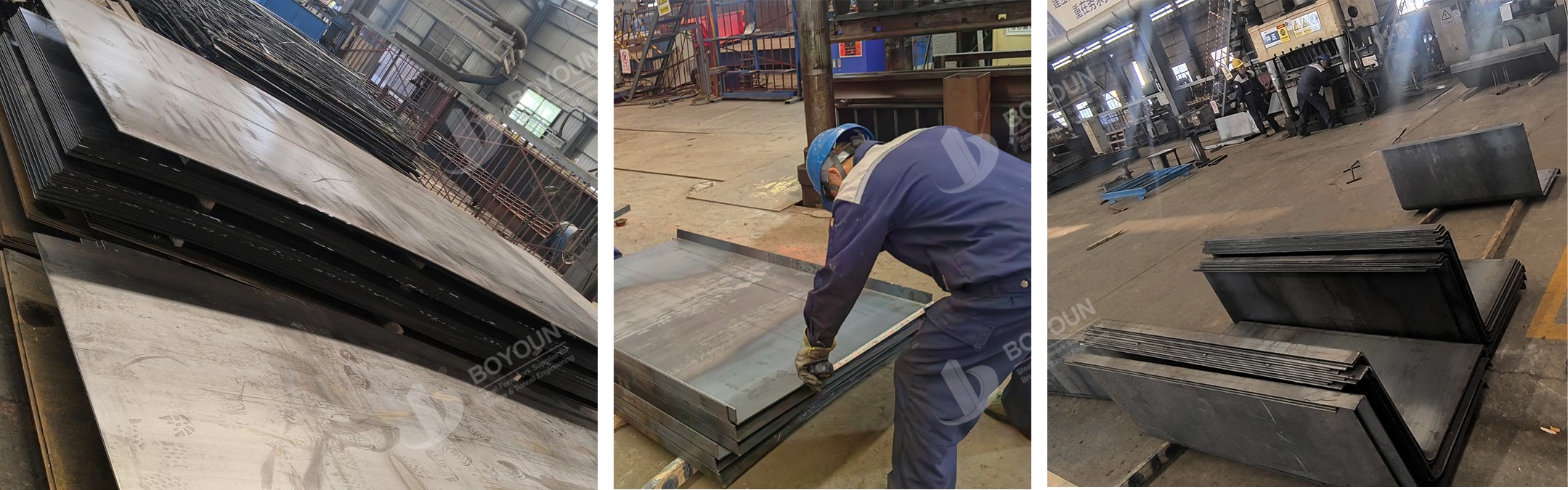

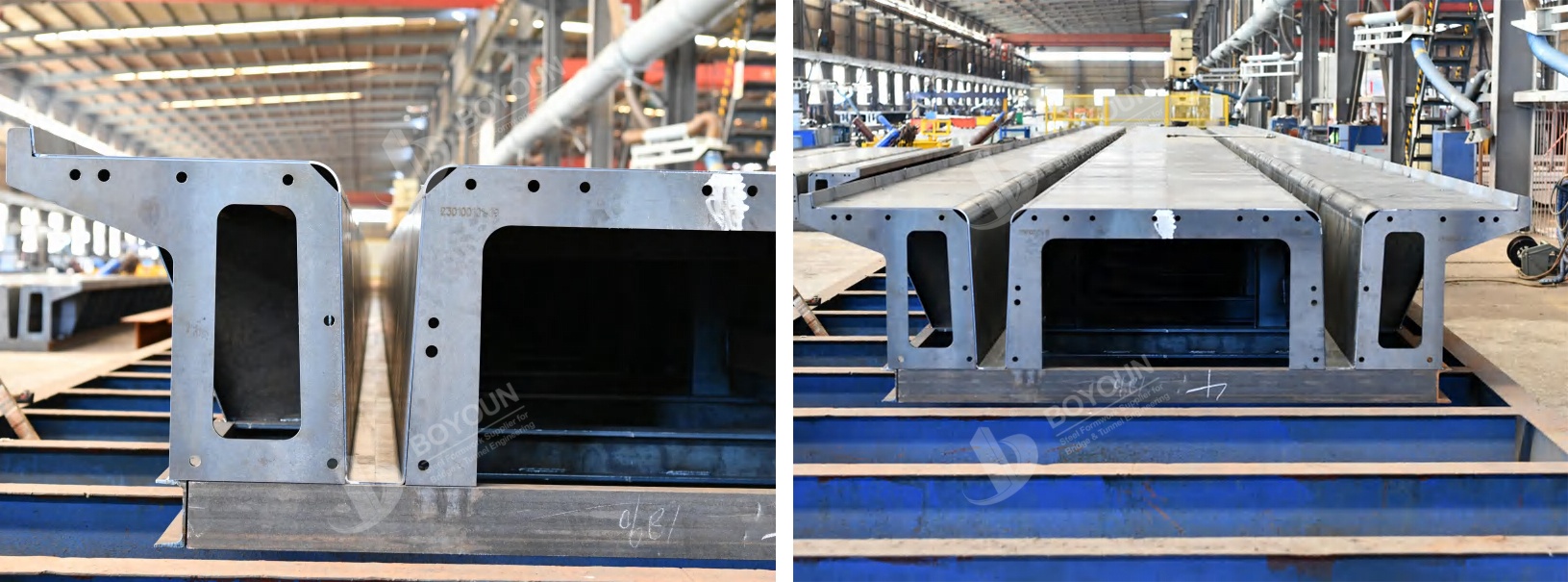

(1) The product is designed to European standards and meets or exceeds the American AWS D1.1 welding standard specifications, imposing extremely strict standards on raw material performance, welding processes, weld quality and appearance, part precision, paint film thickness, and adhesion.

(2) The customer put forward new requirements for process control and documentation throughout production, progress reporting and feedback, process development, and cross-departmental efficient collaboration.

(3) Additionally, the customer set strict and clear requirements for pre-shipment inspection items and standards. A globally renowned third-party professional inspection company commissioned by the U.S. side conducted quality inspections, and the products were only packaged, reinforced, and shipped after passing inspection.

(4) During the early development phase, based on Boyoun's business philosophy and delivery cases of thousands of projects, the customer visited Boyoun's factory for on-site inspection and placed high trust and expectations in Boyoun.

(5) In the early stage of project cooperation, Boyoun's sales team, leveraging years of foreign trade and professional experience, resolved potential language barriers in Chinese-English technical materials and quickly established a collaborative working model agreed upon by both sides. With the customer's approval signatures on English documents, valuable time for early delivery was secured.

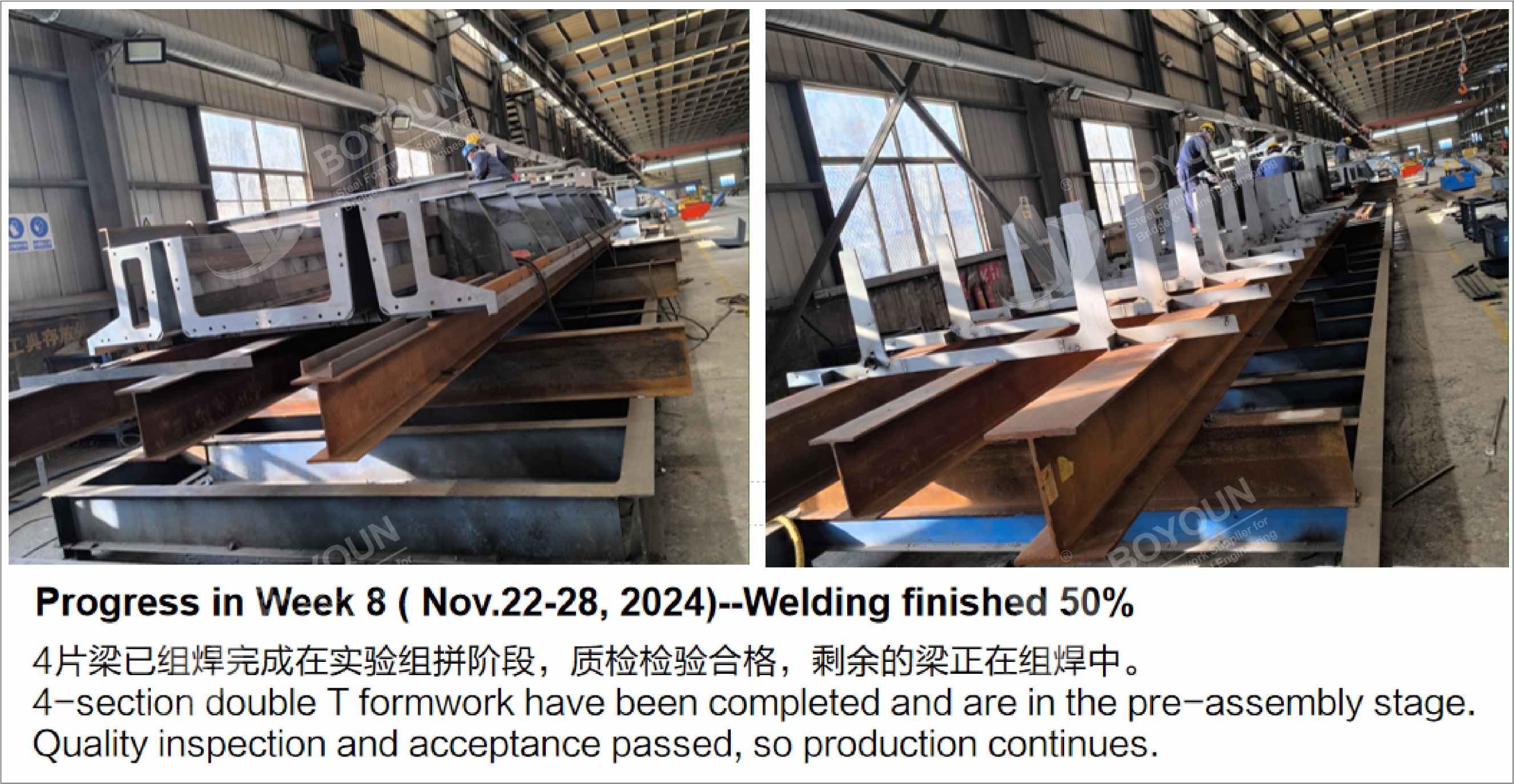

(6) Entering the production phase, the production site and sales team successfully completed multiple tasks at each customer-specified stage. Through the submission of on-site data sheets and reports, batches of photos and videos, and frequent online video conferences, the U.S. side clearly understood production progress and quality control—even without stationing representatives for factory supervision. The customer expressed gratitude for Boyoun's efforts.

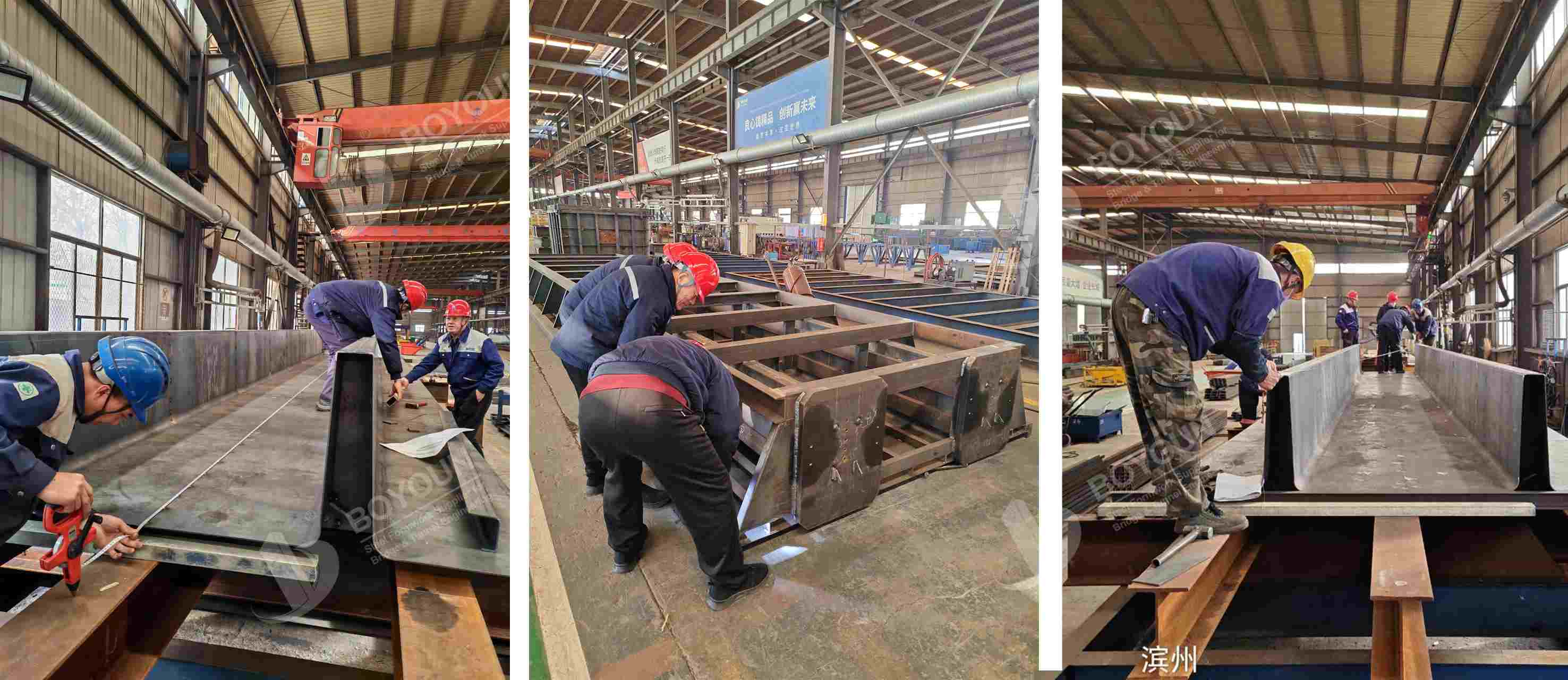

Incoming material inspection, material cutting, self-inspection of assembly welding, and sequential inspection of weld beads

Production progress report to enable customers to clearly grasp production progress and process quality control

When the product manufacturing was completed and comprehensive quality inspection began, a representative from SGS, the internationally renowned third-party inspection agency commissioned by the customer, visited Boyoun's factory for thorough product inspection. Based on the customer's specified inspection items and standards, the SGS representative conducted strict item-by-item testing and ultimately submitted a product quality report exceeding the U.S. customer's expectations. The U.S. customer was overjoyed, exclaiming, "Boyoun's formwork quality surpasses similar products from European companies!"

Boyoun's smooth delivery in the U.S. market has laid a solid foundation for follow-up orders and the expansion into new high-quality standard markets in the future.

At the same time, outstanding manufacturing enterprises represented by Boyoun, which focus on building Chinese national brands and maintaining corporate images, continuously improve product quality and delivery standards, increasingly gaining attention and high praise from European and American customers. More and more representatives of European and American companies are willing to travel to China for factory inspections. We are proud of this!

Boyoun dares to be an industry pioneer, step out of its comfort zone, adhere to the lifeline of product quality, and continuously expand its international vision. By continuously improving and proactively embracing high-standard inspections, we look forward to working with colleagues who are dedicated to building brands, jointly achieving the brilliance of "Made in China" on the international stage.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn