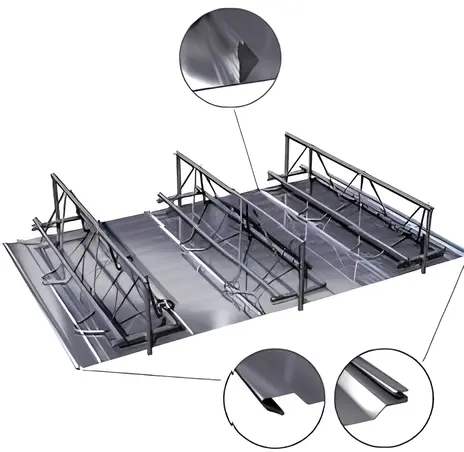

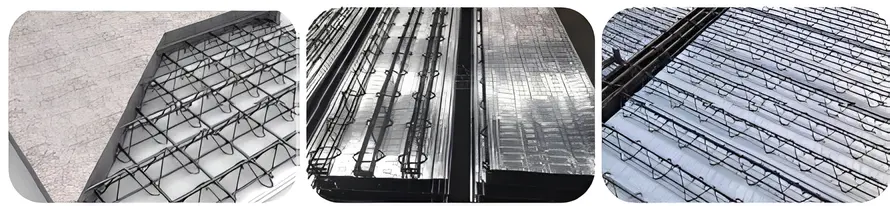

The M-Type Deck Truss is a composite formwork fabricated by processing the steel bars of the floor slab into steel bar trusses in the factory, followed by integral welding of the trusses with galvanized profiled steel sheets. During the construction phase, the M-Type Steel Bar Truss Deck can bear construction loads and be directly laid on beams. Concrete can be poured after simple on-site steel bar binding work. As it fully replaces the function of traditional formwork, it eliminates the processes of formwork erection and removal, significantly improving the efficiency of floor slab construction.

The M-Type Steel Bar Truss Deck features economy, convenience, safety, and reliability. Currently, it is widely used in various structures and construction fields, including multi-story factories, multi-story, high-rise, and super-high-rise steel structure buildings, various irregular floor slabs, concrete structures, and high-speed railways.

Economy

(1) Rational truss force-bearing mode, economical material selection, and obvious comprehensive cost advantage.

(2) Adjustable truss height and steel bar diameter, suitable for floor slabs with large spans.

(3) Can be designed as a two-way slab.

Convenience

(1) Reduces on-site steel bar binding workload by 60%-70%, further shortening the construction period.

(2) Rational truss force-bearing mode provides greater rigidity of the floor deck, which can significantly reduce or even eliminate the need for temporary construction supports.

Reliability

(1) Mechanical properties are basically equivalent to those of traditional cast-in-situ floor slabs, with excellent crack resistance.

(2) Fire resistance is comparable to that of traditional cast-in-situ floor slabs and superior to that of profiled steel sheet composite floor slabs.

(3) The bottom formwork does not participate in force bearing during the service phase, eliminating the need to consider fire protection and corrosion protection issues.

Safety

(1) Uniform steel bar arrangement, with reliable guarantee for the spacing between upper and lower steel bars and the thickness of the concrete protective layer.

(2) Double-folded edge lap design effectively ensures the construction quality of the composite floor slab.

(3) The bidirectional rigidity of the floor slab is similar, which is conducive to the seismic resistance of the building.

(4) The quality of shear stud welding is easier to guarantee.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn