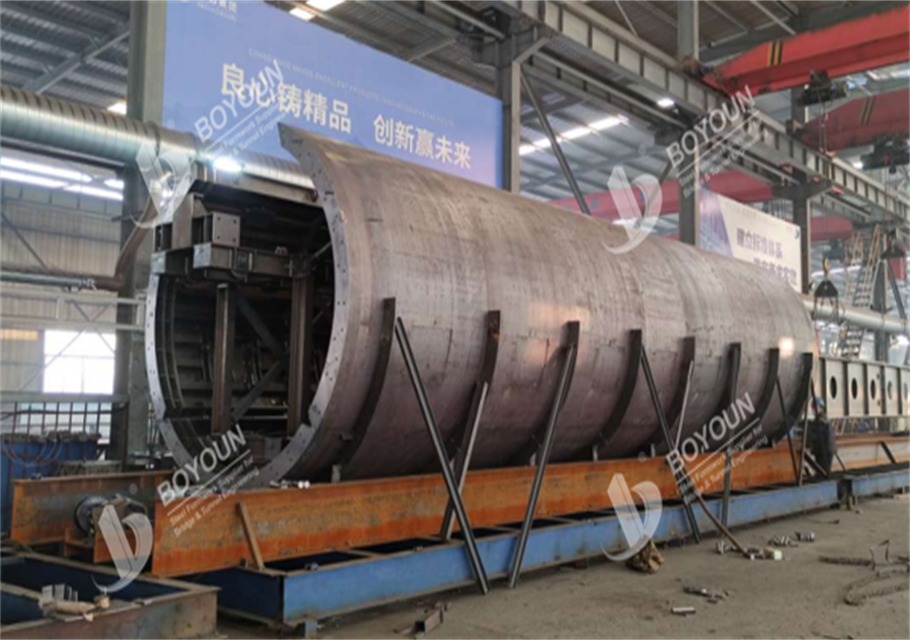

The Full circle tunnel lining trolley is designed for the overall lining of power station tunnels. The bottom, sides, and top of the full circle section of the needle beam trolley-lined tunnel are assembled in one go. The mold erection and demolition are performed by hydraulic cylinders, and the positioning and alignment are performed by the base vertical cylinder and leveling cylinder. The trolley is self-propelled, and the winch on the trolley causes the steel mold and needle beam to move relative to each other, allowing the trolley to move forward and backward.

1. Fast construction progress, high efficiency, and low cost.

2. The entire section is constructed in one go, reducing construction joints and improving concrete waterproofing effect and appearance quality.

3. The trolley has good stability and ensures the lining quality to be solid inside and smooth outside.

4. The trolley's needle beam is foldable, and its formwork is a hinge-type combination that can turn and climb (% slope)

5. Enough space for handling stencil dirt.

6. Low labor intensity, safe, reliable, and easy to promote.

1: How does the needle beam trolley ensure quality pouring?

Answer: Firstly, the formwork design of the trolley has high precision, which ensures that the concrete pouring shape and size meet design requirements. Secondly, the trolley's support system can be adjusted to accommodate different tunnel construction lengths, ensuring that the formwork won't shift or deform during the pouring process. Additionally, the trolley is equipped with equipment such as vibrators, which can make the concrete more dense and improve its pour quality.

2. How to maintain the needle beam trolley?

Answer: To maintain the needle beam trolley, first of all, the residual concrete and other impurities on the surface of the trolley should be cleaned promptly after each use. Secondly, the oil level and operation of the hydraulic system, motor, reducer, and other components should be checked regularly. If any irregularities are discovered, it should be addressed promptly and the worn parts replaced. Furthermore, the track of the trolley should be regularly cleaned and lubricated to maintain its normal operation.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn