Introduction

A steel box girder is a commonly used structural form for long-span bridges, named for its box-shaped cross-section. Its main body is composed of a top plate, bottom plate, web plates, and transverse/longitudinal diaphragms through a full welding process. The top plate mostly adopts an orthotropic deck design with longitudinal stiffeners, featuring a wide and flat profile as well as strong bending and torsional resistance, making it suitable for long-span scenarios such as urban interchanges and overpasses.

Cross-sectional form: Divided into single-box single-cell, single-box double-cell, and multi-box cell types. The web plate thickness ranges from 8mm to 20mm, and the top/bottom plate thickness ranges from 12mm to 30mm. Some bridges adopt U-rib stiffening (U-rib height: 200mm-300mm) to enhance torsional resistance.

Connection technology: Factory production uses robotic welding assembly lines, with the proportion of full penetration welding reaching over 95%. On-site connections are mainly bolt-welded combinations, and some projects adopt full bolted connections to improve assembly accuracy.

Cross-sea bridge: Suitable for long-distance marine passage. For example, the Shanghai Donghai Bridge (the marine section is 28km long, with 107 steel box girders connected by full bolts, featuring strong wind and wave resistance).

Urban viaduct and maglev dedicated line: The steel box girder bridge of the Shanghai Maglev Train adopts specially manufactured steel box girders to adapt to the laying of maglev tracks, with a deck flatness error of ≤2mm/m.

Airport hub supporting facilities: The double-deck departure bridge of Beijing Daxing International Airport adopts a double-deck steel box girder structure (the upper deck is 52m wide and the lower deck is 37m wide). The curved deck is adapted to the streamline design of the terminal building, with a total steel consumption of 35,000 tons.

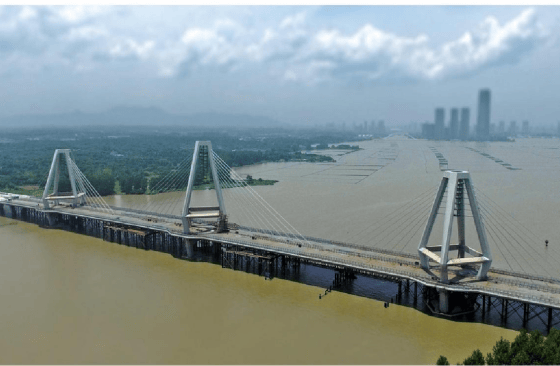

Case 1: Fanli Bridge over Taihu Lake

This bridge totals 1,376 m in length: identical cross-section steel box girders for the offshore portion and 30 m-span cast-in-place concrete beams for the onshore. Its main spans are 82 m, 168 m, 168 m and 82 m, with the main bridge being a triple-tower, single-cable-plane steel girder cable-stayed structure (tower-beam separated bracing system). Fan-arranged stay cables include seven pairs per side on side towers and nine pairs per side on the center tower. Fabricated from Q345qD steel, it has a total steel consumption of 16,300 tons.

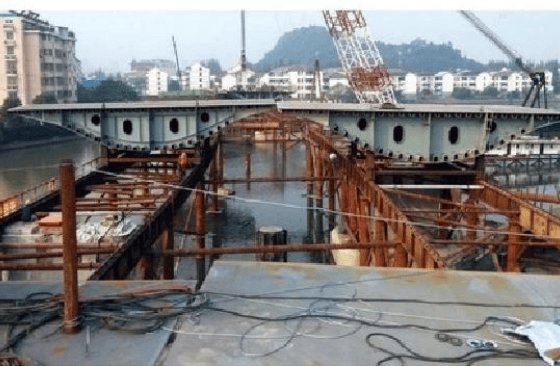

Case 2: Maanshan Road Bridge in Kunshan

This bridge is composed of continuous steel box girders with variable depth.The main bridge has left and right units,each of which has three spans.The left unit has a total span of (31+75+47) m,while the right unit has a total span of (42+79+33)m.Material grade used for the steel girders is Q345qD.A total of 4,100 tons of steel was used.

Case 3: Meilin Bridge in Yixing

Case 3: Meilin Bridge in Yixing

This bridge is a three span continuous basket arch bridge.The spans are 66m,168m,and 66m.

The bridge consists of steel basket arches,box girders,and concrete decks.Steel box girders were used in the side spans,while composite box girders were used in the middle span.Material grade is Q345qD.A total of 5,076 tons of steel was used.

(1)Excellent torsional resistance and stiffness: The box-section has a large moment of inertia, and its torsional stiffness is 5-8 times that of an I-beam with the same span, making it suitable for long spans (single span up to 168m) and curved bridge decks.

(2)High driving comfort: The bridge deck is flat without obvious joints. The deck flatness of the steel box girders on the Shanghai Donghai Bridge is controlled within 3mm/4m, meeting the driving requirements of expressways.

(3)High degree of modularization: Steel box girders can be prefabricated in standard segments (12-24m per segment).

Q1: How is the deck flatness of steel box girder bridges controlled?

A1: Flatness is controlled through "factory precision + on-site assembly": ① In the factory, CNC edge milling machines are used to process plate units, and automatic welding robots control deformation; ② On-site, 3D measurement systems (accuracy ±1mm) adjust segments, and welds are ground after welding.

Q2: What information do I need to provide to get a quotation?

A: You need to provide 5 key pieces of information: 1. Building appearance details (shape, size, height); 2. Required material standards; 3. Load requirements (live/snow/wind load, etc., and design standards if applicable); 4. Coating standard requirements; 5. Expected delivery standards.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn