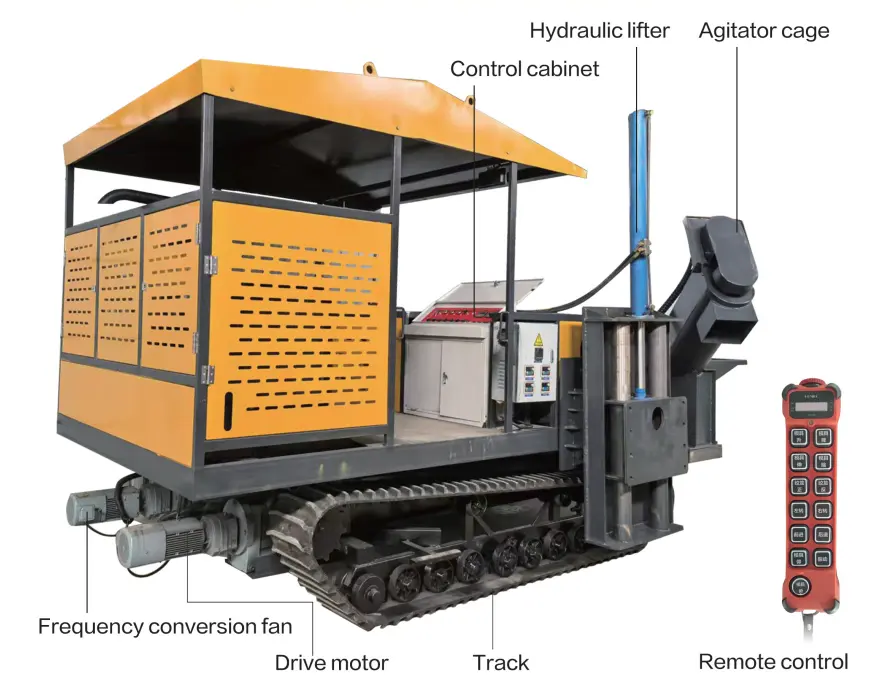

A slipform curb machine is used for shoulder slipforming,drainage ditch slipforming, curb forming and other operations. It consists of a traveling mechanism,vibration mechanism,forming mechanism,generatorand power distribution system.

Feeding Method | Hydraulic Screw Feeder |

Total Weight | 7-17T(excluding mold) |

Working Method | Dual AutomaticLeveling Instrument Control +Bidirectional Transverse Wave Instrument |

Engine | Turbocharged Six-cylinder Engine |

Molding Method | High-frequency Vibration Type |

Engine Start Method | Electric Start |

Sunshade Shed | Detachable Steel Shed |

Applicable Material | Concrete |

Working Speed | 1-10m/min |

Control Method | Control Cabinet Manual Control+Wireles Remote Control |

Hopper Capacity | 1.6m³ |

Driving Method | Dual Reduction Travel Motor |

Speed Regulation Method | Inverter Stepless Speed Regulation |

Transmission Type | Electromechanical Control |

Generator | 50-100kw |

Hydraulic Drive Method | Oil Pump Motor Direct Drive |

Track Type | 50cm Rubber or Steel Track |

Oil Pump Motor | 15kw Direct-connected Special Oil Pump Motor |

Water Tank Capacity | 500L |

Machine Cleaning | Equipped with High-pressure Washer |

Fuel Tank Capacity | 200-360L |

Hydraulic Oil Capacity | 120-150L |

Fuel Consumption | 4L |

As special equipment in road construction projects,it utilizes engineering-standard carriers(including asphalt products and cement concrete)to build parapet,drainage ditches and other facilities on both sides of roads.

By injecting concrete into precision steel molds,matching high-frequency vibrators,and achieving one-time forming through high-performance extrusion and compaction,it en- sures construction flatness,linear straightness,surface smoothness,and no honeycombing or sand holes.

PLC Control Cabinet

Equipped with a high performance controller and automatic numerical control design, the console adapts to various construction requirements with simple operation.

Remote Control Operation

Wireless remote control and intelligent design enable unmanned construction for greater convenience.

Turbocharged Engine

Powered by Weichai, it guarantees fuel economy and continuous power output, ensuring smooth and efficient construction operations.

Enlarged Hopper

Enlarged hopper with hydraulic feeding design for faster feeding speed.

High-performance Tracks

Tracks offer good shock absorption, high strength, smooth driving, and adaptability to various terrains.

Automatic Leveling

Hydraulic control adjusts the mold height automatically up and down according to the ground, ensuring high precision.

Q1: Can one slipform curb machine be used for both parapet and curbs?

Yes. Most multifunctional slipform curb support quick mold replacement. By switching between parapet molds and curb molds (customized to project dimensions), the machine can handle both types of construction tasks, which helps reduce equipment investment costs for construction companies.

Q2: Do you provide customized molds for special-shaped parapet and curbs?

Yes. We offer customized mold design and manufacturing services according to your project drawings. Whether it is special-shaped curbs with drainage grooves or parapet with anti-collision slopes, Boyoun can tailor molds to meet your specific structural requirements, ensuring precise forming and compliance with design standards.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn