The intelligent spraying system consists of four major components: PLC (Programmable Logic Controller), circuit control, spraying, and water supply.

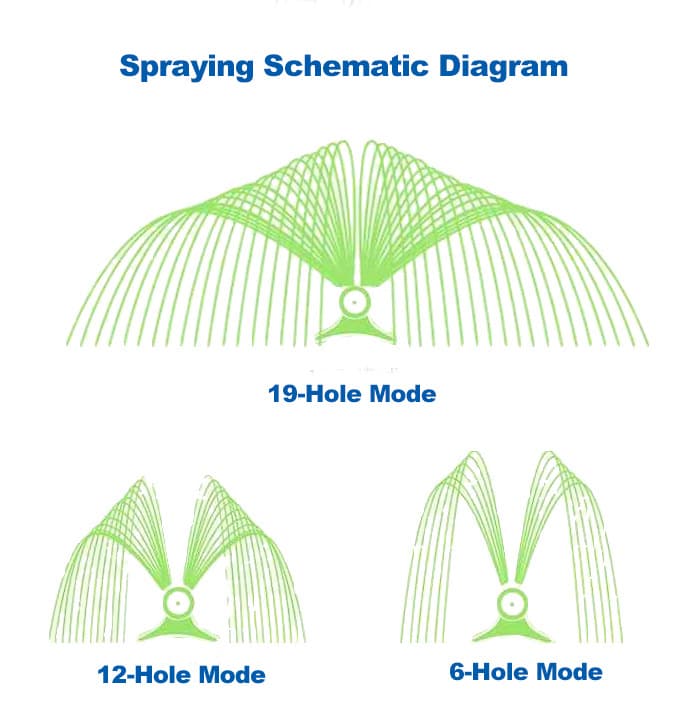

Operation Schematic of the Automatic Spraying System

Turn on the main power switch of the automatic control system, set the total duration and waiting time of the sprinkling cycle of the control system, and the pressure water pump starts to operate. Turn on the power switch, adjust the sprinkling time and set it to the desired duration; the sprinkling will stop automatically when the set time is up, and the system will switch to the next working cycle. The atomizing nozzles can be activated simultaneously to suppress on-site dust, meeting the environmental protection requirements of the construction site.

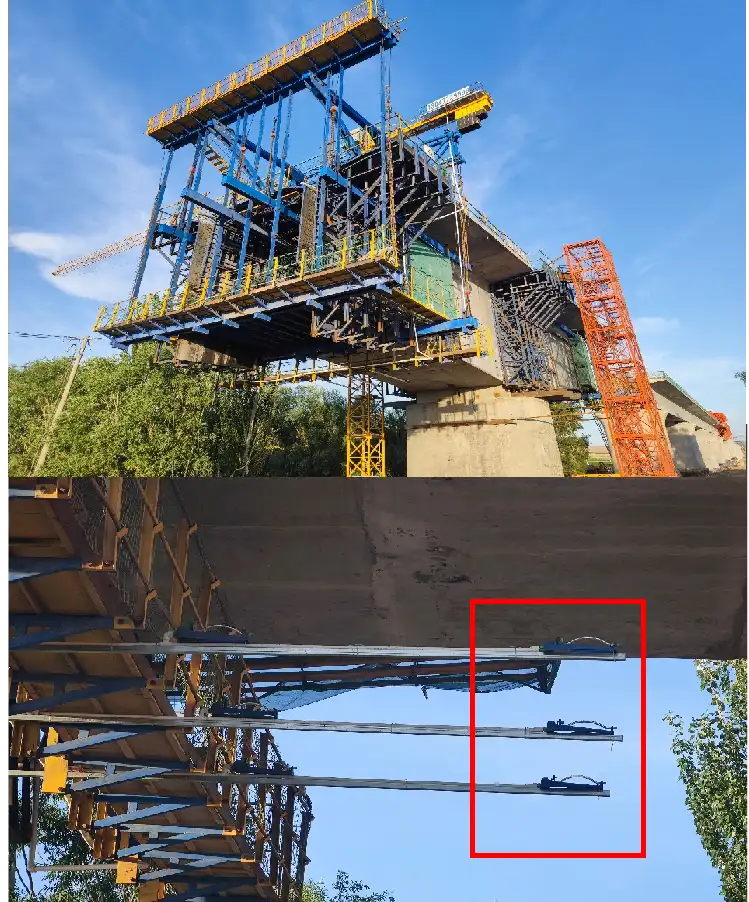

The bridge intelligent spraying system is an automated bridge maintenance system, mainly used for daily cleaning, cooling, dust removal, spraying of maintenance agents, and spray dust suppression of bridges.

(1)Key technologies for accelerating bridge construction cycles.

(2)The water mist it sprays is uniform, meeting the all-weather and full-wetting curing quality standards with remarkably significant curing effects.

(3)From water supply to the completion of operations, the entire process is basically fully automated and remotely controllable, greatly reducing labor intensity and improving labor productivity.

(4)It features low cost, convenient installation and maintenance, and water conservation.

(5)It provides moisture retention, thermal insulation, inhibits crack formation, saves labor and energy, and reduces curing costs.

(6)It solves the curing challenge of "dead corner" areas at the junction of cantilever-cast flange plates and web plates.

(7)It reduces the time for manual high-altitude operations and avoids the randomness of manual operations.

(8)It emphasizes environmental protection and can play a role in dust suppression.

Function | Intelligent Spraying System | Manual Spraying |

Maintenance Time | 7×24 Hour All-Weather | Daytime, every 2 hours |

Water Mist | Uniform | Non-uniform |

Coverage | Full-position | Misses bottom flanges & slab |

Convenience | Fully Automatic Timed and Quantified Spraying | Prone to insufficient curing time and requires high-altitude operations |

Manpower | No dedicated staff needed | 5-6 staff required |

Labor Intensity | Low | High |

Cost | One-third of the cost of manual spraying, Reusable and recyclable | High labor & management cost One-time investment, non-recyclable |

Q1: What is the core function of the intelligent sprinkler system?

A1: It is mainly used for the maintenance of bridge concrete structures (such as beam bodies, cap beams, and piers). By automatically controlling the sprinkling time, water volume and frequency, it maintains the humidity of concrete, prevents cracking, and improves strength.

Q2: What are the advantages of the intelligent sprinkler system in maintenance effect compared with traditional manual watering?

A2: It avoids the problems of missing spraying, insufficient spraying and uneven spraying in manual maintenance. The concrete strength improvement is more stable, the crack occurrence rate can be reduced by more than 60%, and it can reduce water waste (water saving rate is about 40%).

Q3: Which types of bridges are suitable for the intelligent sprinkler system?

A3: It is applicable to various types of bridges such as cast-in-situ beams, precast beams, continuous beams and rigid frame bridges.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn